Your Concerns; We Are Aware

CONTACT US

Get Connected With Us

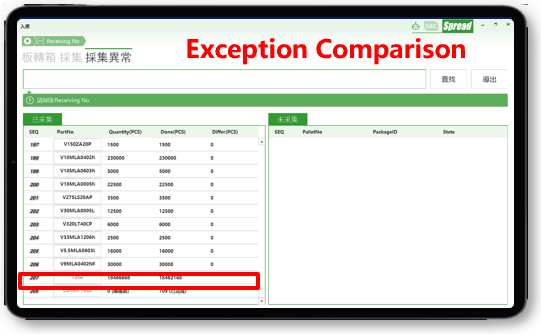

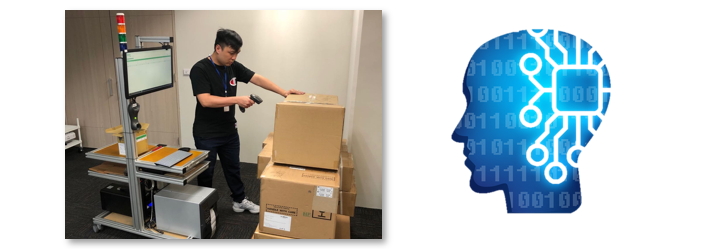

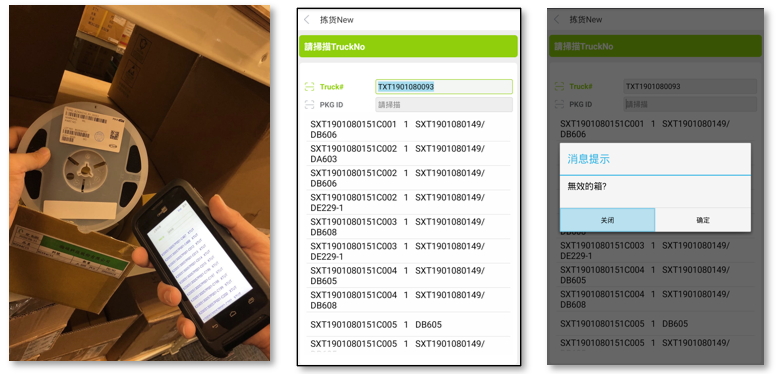

Hong Kong Smart Warehouse

Address: No. 50, Shek Wu Wai Road, Yuen Long, N.T., Hong Kong

____________________________

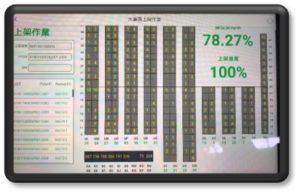

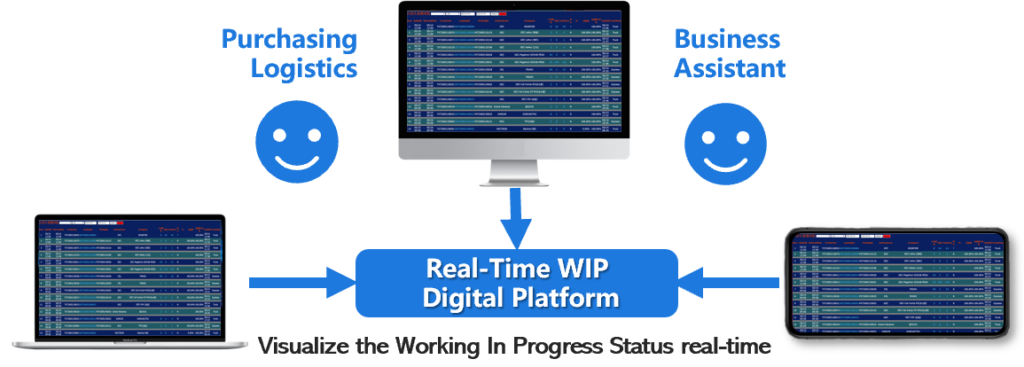

Taiwan Control Tower

Address: 7F., No.81, Xinhu 1st Rd., Neihu Dist., Taipei City 11494